MSc thesis project proposal

Perovskite-based MultiLED through band-gap modulation

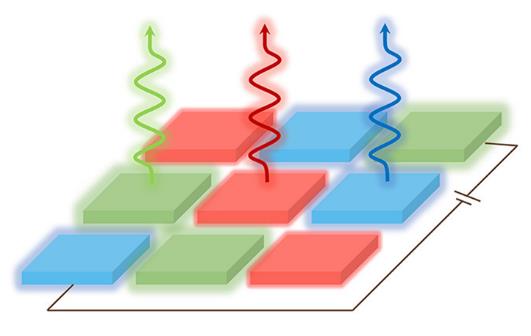

Perovskite-based light emitting diodes (LED) are gaining increasing attention due to their improved

external quantum efficiencies. The umbrella of applications of this family of LEDs are quite large due to

their tunable bandgap through engineering the lattice structure and composition, which makes them the

perfect candidate for the emitting layer, which is sandwitched between the electron and hole transport

layer comprising of suitable materials (Figure 1). However, the promise of scaling up these devices with

bespoke structure of active materials would require development of large area processing routes through

industry compatible processes. Vacuum-based deposition methods are one of the potential technologies to

address this challenge, which has demonstrated large-scale, reproducible processing of devices like solar

cells, and transistors.

However, the external quantum efficiency of these devices strongly relies on the optimization of the deposition process as it controls the homogeneity, defect concentration as well as crystallinity of the perovskite layer, which in turn affects the charge carrier mobility, life time and trap densities.

In this project we aim to develop perovskite-based light emitting devices using the recently the perovskite line established in the cleanroom by the photovoltaics and materials group (PVMD/ESE). The band gap of the perovskite emitting layer will be tuned through optimization of the composition and deposition conditions.

Furthermore, MultiLED chip will be developed using a shadow masking technique.

Assignment

- Literature study to assess the state of the art

- Cleanroom processing training

- Optimization of the deposition conditions for the perovskite layer

- Fabrication and device characterization.

- Fabrication of Multi LED through shadow masking technique.

- Reporting.

Project supervisors:

Henk van Zeijl (ECTM, Department of Microelectronics)

Moumita Rana (PVMD, Department of Electrical Sustainable Energy)

Contact

dr. Massimo Mastrangeli

Electronic Components, Technology and Materials Group

Department of Microelectronics

Last modified: 2025-07-30